ARC-1000 PVD Arc Deposition Coating Machine

PVD coating is taking place in a vacuum chamber by process of evaporation. Titanium is vaporized through magnetron sputtering or multi arc. We produce the PVD systems with both technologies. The positively charged titanium ions are mixed with nitrogen, argon, acetylene or oxygen gas to form a plasma. The positively charged titanium plasmas are attracted to the negatively charged workpiece, thereby forming a thin and uniform coating on the piece.

ARC-1000 is the most popular model of PVD coating machines in our company. This model is designed for functional applications.

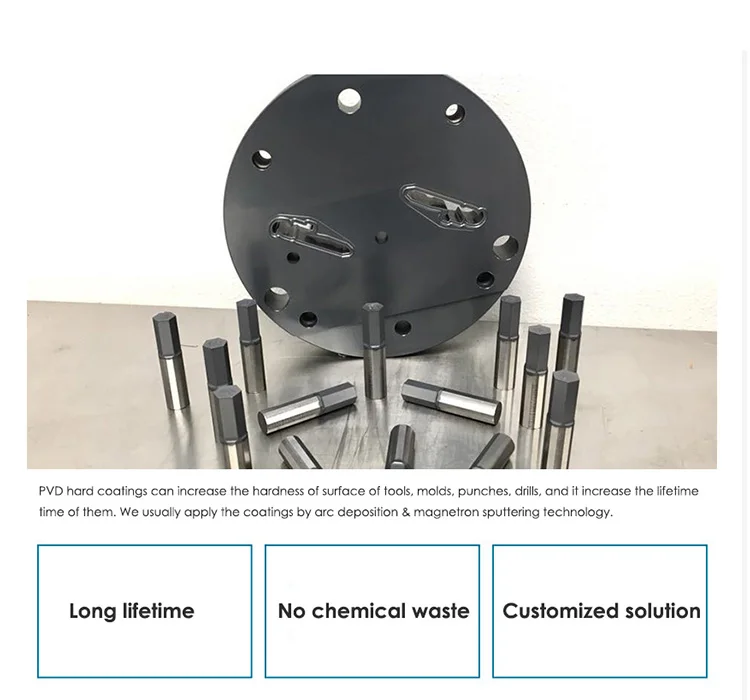

Application:

Metal Forming Dies

Plastic Injection Molding

Drilling bits

Cutting tools, knife and blades