MF(Medium Frequency) Unbalanced Magnetron Sputtering Sources

Description

Unbalanced magnetron sputtering technology is to adjust the magnetic flux of the inner and outer magnetic poles of the magnetron sputtering cathode, so that the magnetic flux of the outer magnetic pole is greater than that of the inner magnetic pole, resulting in incomplete closure of the magnetic lines of force of the two poles on the target surface. A portion of the magnetic field lines may extend into the substrate region along the edge of the target, such that a portion of the electrons may extend into the substrate along the magnetic field lines, increasing the plasma density and gas ionization rate in the substrate region. This sputtering technique can more effectively use the magnetic field to confine the charged particles and improve the sputtering efficiency and coating quality.

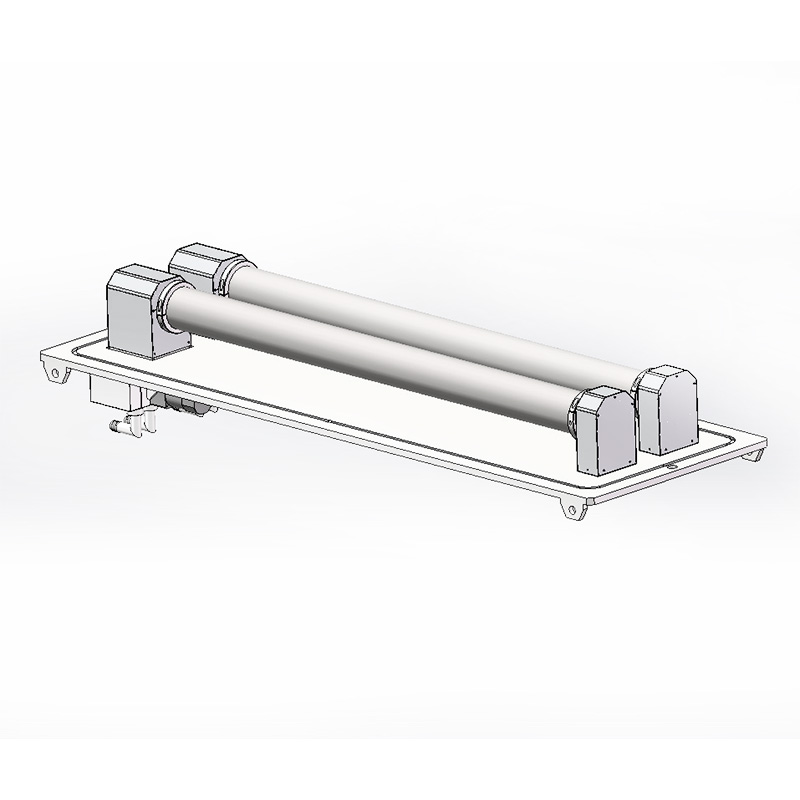

Name: Twin (Medium frequency) MF magnetron sputtering for PVD coating

Type: Rotary cylindrical sputtering cathodes or planar

Application: For magnetron sputtering deposition

Size: Customized

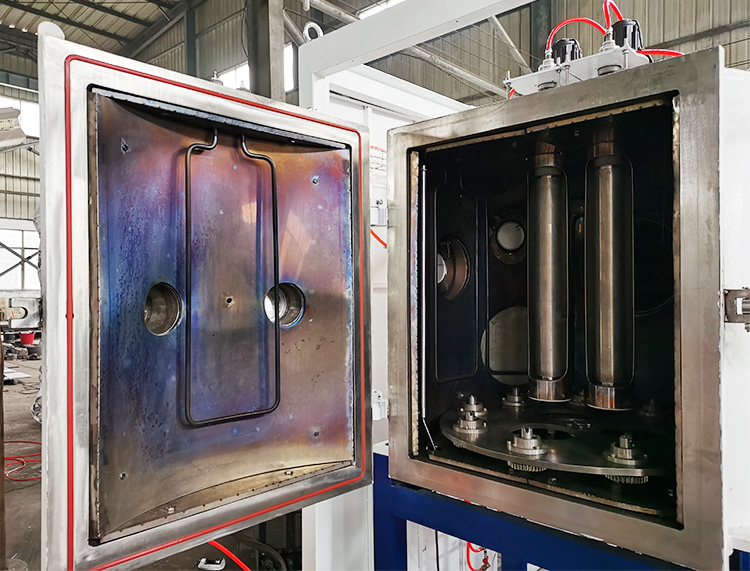

(Mid-frequency magnetron sputtering installed in a PVD coating system)

Design advantages

Improve coating quality: Unbalanced magnetron sputtering technology can increase the plasma density and gas ionization rate in the substrate area, thereby improving the quality and uniformity of the coating.

Improve the sputtering efficiency: due to the extension of the magnetic field lines, more electrons can participate in the sputtering process, thereby improving the sputtering efficiency.

Expand the scope of application: Unbalanced magnetron sputtering technology is suitable for coating a variety of materials, including metals, alloys, compounds, etc., with a wide range of applications.

This coating technolgy can be used for applying different decorative PVD colors including very dark black on substrates. It does not produce too much heat during the vacuum sputtering process, so it is appliable for different base materials, such as plastic, stainless steel, ceramic, glass, etc.