Physical Vapor Deposition PVD Coating Machine

Hongfeng VAC mainly these types of vacuum coaters, such as the coating machine for vacuum metallizing, DC and MF(mid-frequency) magnetron sputtering deposition, cathodic arc deposition( also named arc ion plating).

(Vacuum Metallizing Coating Machine)

Some of the applications of vacuum metallizing coating equipment:

(Coffin accessories) (Cosmetic plastic caps after coating and coloring)

(Car lamps after vacuum chrome plating) (Trophies with vacuum coatings+coloring)

Vacuum metallizing coating process is the best option for making metallic coatings on plastics. It's efficient, low average production cost, easy operation. The raw material of coating is mainly aluminum, after load the pieces into the vacuum chamber for around 15 minutes, you can pick up the products with very bright mirror finishing.

(Magnetron Sputtering Coating System)

Typical applications of magnetron sputtering:

(Glass mirror making) (Food grade plastic cutlery coating with stainless steel)

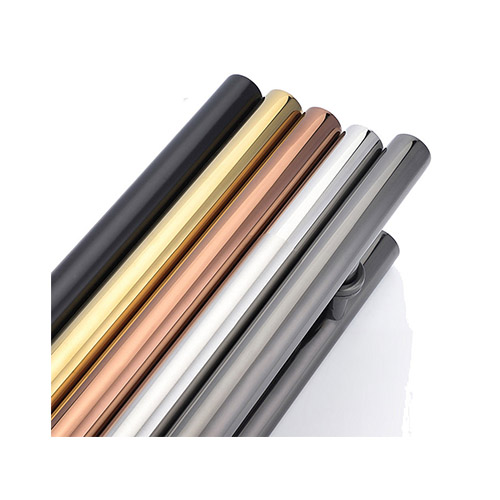

(Decorative PVD sputtering coating on sanitaries) (Copper coatings on ABS plastic base material)

Magnetron sputtering process does not produce a lot of heat during working. It is universal for different base materials, including plastic, glass, ceramic, metals). This is the most common technology we used for inline vacuum coaters. It produces high quality and high uniformity thin film deposition coatings on products, to provide the products with decorative colors, or functional abilities, such as high reflection, high conductivity, etc.

(Cathodic Arc Depostion Machine)

(Decorative PVD coatings on SUS, hybrid PVD arc + sputtering) (Harden protective coatings on tools made by PVD Cathodic Arc Deposition)

Cathodic arc evaporation process makes a lot of heat during working. So this process usually works for the materials which can bear high temperature from over 100°C. It is a kind of efficient way to make coating films. It can be used for both of decorative and functional coating applications. It's a mature PVD coating technology.

PVD is Physical Vapor Deposition, mainly includes arc ion plating(or cathodic arc evaporation), magnetron sputtering and vacuum metallizing coating technology.

The applications for PVD is a lot. It can be use for coatings on plastic, metals, glass, ceramic, etc.

PVD requires good conditions for substrates. The substrates must be dry, clean and smooth. And in functional PVD coating, the hardness of substrates is better higher than 55RC.

Hongfeng VAC produces different types of PVD coaters. Horizontal or vertical, the vacuum chamber with one or two doors, batch type or continuous type.

You may tell us the base material and the max. size of your products, so we can make you a solution. We also provide accessories for our PVD systems.

.jpg)

_small.jpg)