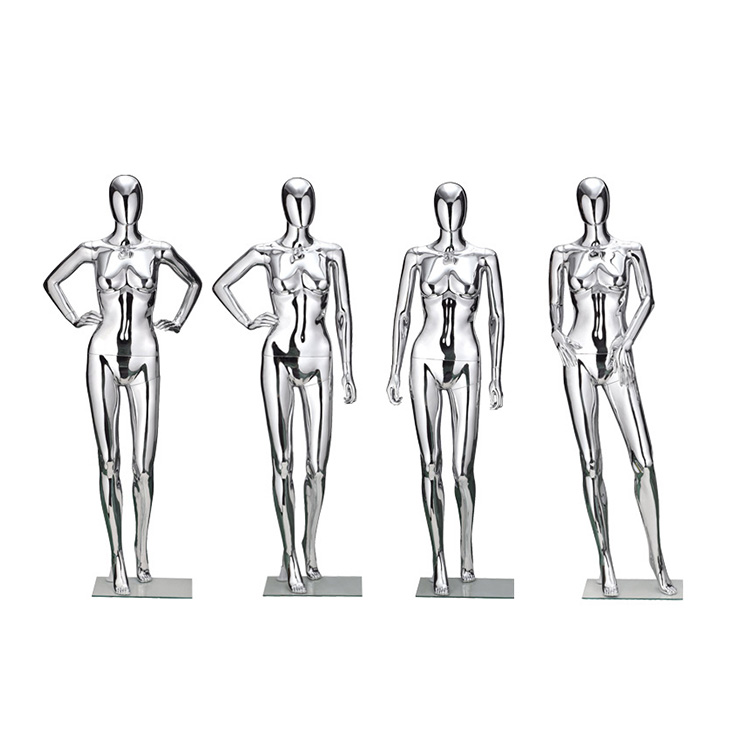

Vacuum Metallization Machine for Mannequins

1. General description

The mannequins vacuum coating machine is an equipment specially used to deposit metal on the surface of the mannequins, and achieves metallization and mirror coating effects through vacuum coating technology. It is widely used in clothing display, artistic creation, industrial design and other fields.

2. Working principle

1. Vacuum environment:

- Pump the coating vacuum chamber to a high vacuum (usually 10⁻³~10⁻⁵ Pa) to eliminate the interference of air molecules and ensure the purity of the film layer.

3. Coating method:

- Physical vapor deposition (PVD): Common methods include:

- Evaporation plating: The metal (usually high-purity aluminum) is evaporated by resistance heating and deposited on the surface of the model.

- Magnetron sputtering: Use plasma to bombard the target material, and the sputtered atoms are deposited into a film (suitable for high melting point materials such as chromium and titanium).

- Ion plating: Combining evaporation and plasma technology, the film layer has stronger adhesion.

4. Film formation process:

- Metal atoms are directionally deposited in a vacuum environment to form a uniform and dense nano- to micron-scale film.

5. Main components of the equipment

1. Vacuum system:

- Mechanical pump: primary vacuum.

- Molecular pump/diffusion pump: achieve high vacuum.

- Vacuum gauge: monitor the pressure in the vacuum chamber.

2. Coating chamber:

- Made of stainless steel or carbon steel, with built-in rotating bracket (to ensure uniform coating of the model).

3. Evaporation/sputtering source:

- Evaporation coating system, magnetron coating system (sputtering).

4. Control system:

- PLC or touch screen control to adjust parameters such as vacuum degree, temperature, coating time, etc.

5. Gas distribution system:

- Gas introduction (such as argon for sputtering), cooling system, safety interlock device.

6. Applications

1. Fashion and display:

- Coating clothing models with metallic luster (gold, silver, rose gold) to enhance visual impact.

2. Art and decoration:

- Create mirror or color art installations (interference colors achieved through multi-layer coating).

3. Industrial design:

- Functional coating (such as conductive and antistatic coating for smart wearable models).

7. Operation process

1. Pretreatment:

- Clean the surface of the model (degreasing and dust removal), and spray primer if necessary.

2. Clamping:

- Fix the model on the rotating bracket to ensure that there is no obstruction.

3. Vacuuming:

- Vacuum in sections to the target vacuum degree.

4. Coating:

- Choose evaporation or sputtering according to the material, and control the thickness (usually 50-500nm).

5. Post-treatment:

- Coat the protective layer (such as UV paint) to prevent oxidation or scratches.

8. Main technical parameters

- Vacuum degree: ≤5×10⁻⁴ Pa

- Coating thickness: 0.1-1μm (adjustable)

- Model size limit: diameter ≤1m, height ≤2m

- Power consumption: 20-50kW (depending on the coating method)

9. Selection suggestions

- Small laboratory: choose a desktop evaporation coating machine (low cost, suitable for aluminum film).

- Industrial grade requirements: magnetron sputtering equipment (various film layers, strong adhesion).

If you need more specific equipment models or process solutions, please provide further details of your requirements and contact us.