Decorative PVD Coating Equipment For Stainless Steel Custom-Fabricated Items

Based on the theory of cold cathode vacuum arc discharge, the multi-arc ion plating machine forms high current density spots on the surface of the target through the arc, evaporates and ionizes metal vapor (such as Ti, Cr), and produces high-energy positive ions (such as Ti). Under the action of bias electric field, these ions combine with reaction gas (such as N N) and deposit on the surface of the workpiece to form TiN, CrN and other high-hardness coatings.

Advantages of the equipment:

High ionization rate: significantly improve the binding force of the coating to ensure that the coating is tightly bonded with the substrate and is not easy to fall off.

Fast deposition rate: Compared with the traditional coating technology, the efficiency is improved, which is suitable for large-scale production and meets the needs of batch processing of furniture accessories.

The uniformity of the film is good: the high kinetic energy of ions can evenly cover workpieces with complex shapes, such as curved surfaces, corners and other parts of furniture accessories.

Excellent coating performance: TiN coating is golden yellow, with high hardness, wear resistance and corrosion resistance, which can prolong the service life of furniture accessories.

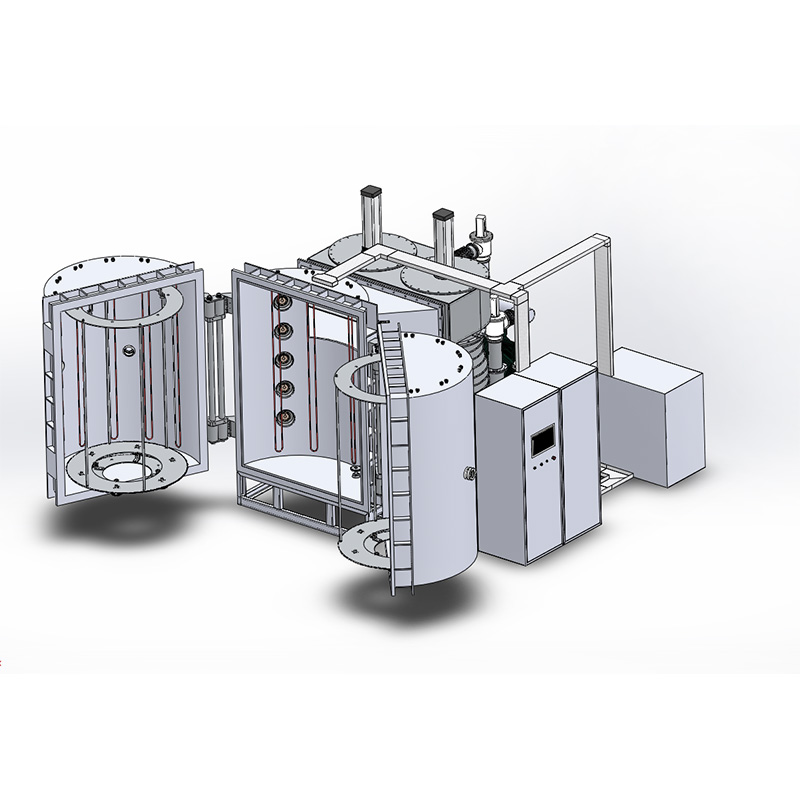

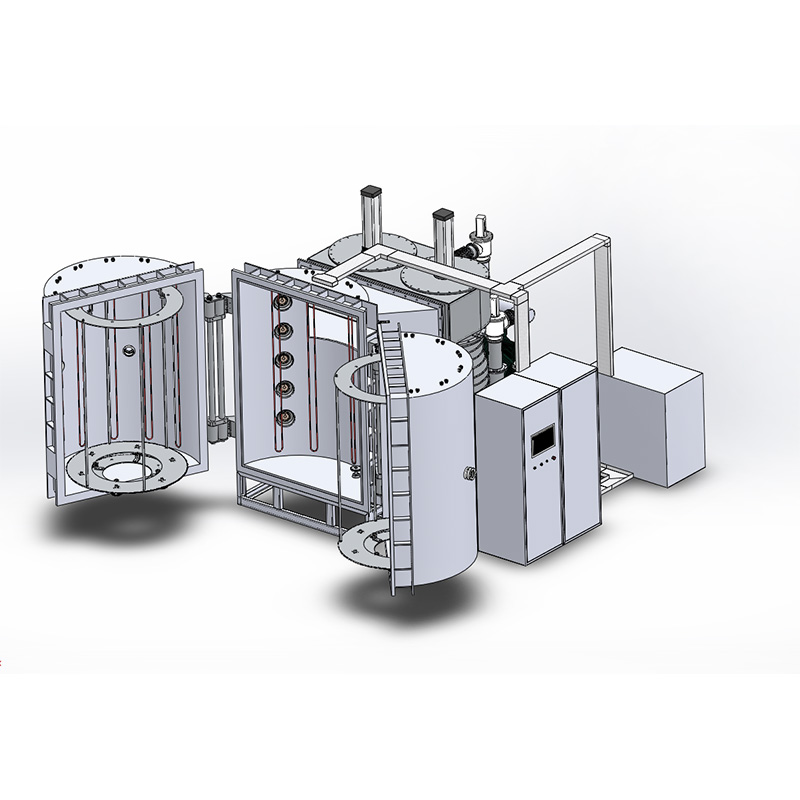

Main components of the equipment

Vacuum coating chamber: provide high vacuum environment (limit vacuum up to 3.0 × 10 0 × 10 Pa) to ensure no pollution during coating.

Arc source: 100mm in diameter with high power multi-arc ion plating power supply.

Vacuum acquisition system: including slide valve pump, Roots pump, diffusion pump, etc., rapidly pumping to the required vacuum degree (pumping to 5.0 × 10 × 10 ³ Pa in no-load atmosphere for less than 25 minutes).

Bias power supply: provide 0-1200 V bias to control the ion deposition energy and optimize the coating structure.

Carousel for products: support up rotation or down rotation + rotation frequency conversion stepless control to ensure coating uniformity.

Gas and water system: precisely control the flow of reaction gas (1-4 MFC), and maintain the stable operation of the equipment through the water cooling system.

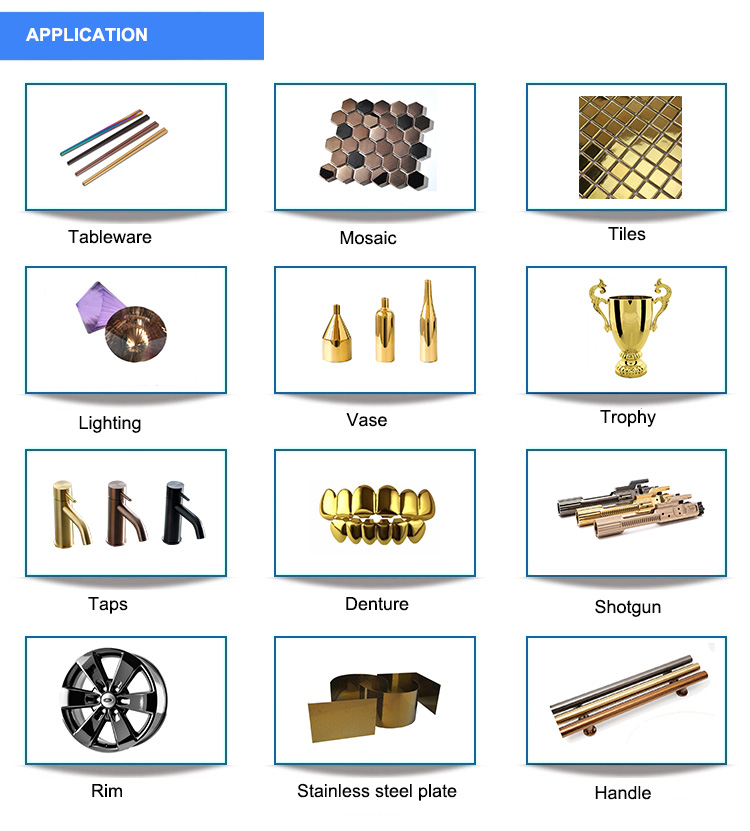

Main application industries:

- Stainless steel furniture: display shelves and engineering products are plated with golden TiN coating to improve the appearance grade.

- Hardware accessories: door locks, handles, handicrafts, etc. Through the coating to obtain the effect of imitation gold, instead of high-cost pure gold jewelry.

- Automobile and motorcycle parts modification: such as wheel hub, decorative strip, etc., enhance wear resistance and visual appeal through coating.

- Bathroom accessories: Faucet and shower head are plated with TiN coating to improve corrosion resistance and prolong service life.

- Lamps and lanterns accessories: The lighting frame presents metallic luster after coating, which enhances the decorative effect.