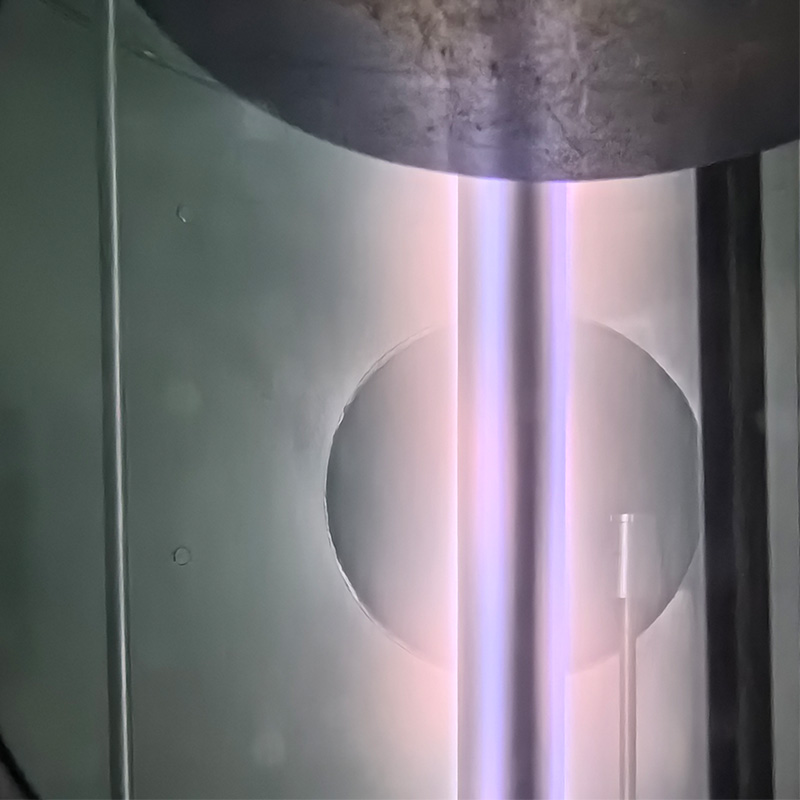

Cylindrical DC Magnetron Sputtering Coating Cathode

Magnetron sputtering is a fast, affordable, high-speed sputtering system that produces superior film quality. Sputtering equipment is equipment for forming thin films, which used phenomenon spraying, in which ionized Ar gas, under the action of a plasma discharge, collides with a target at high speed, and target atoms ejected during the collision are deposited on the substrate. It can be used to produce metal films (in particular, films of refractory metals can also be obtained) that insulate films, conductive films, protective films, reflective films, translucent films, alloys and solid solutions, catalysts and other coated ones.

Sputtering cathode is working in the vacuum coating system

Name: Customized magnetron sputtering cathode for PVD coating

Type: Rotary sputtering cathodes or planar

Application: For magnetron sputtering deposition with Direct metal coatings, such as aluminium, stainless steel, chrome, silver, titanium, etc

Applicable material: Different kinds of material

Size: Customized

Main Features:

High target utilization rate: The rotating cathode makes the target surface uniformly bombarded by the ion beam, thus improving the target utilization rate.

High sputtering rate: By optimizing the magnetic field and rotation speed, higher sputtering rates can be achieved.

Good process stability: The rotating cathode helps to reduce the unstable factors in the sputtering process and improve the stability of the process.

Rotating magnetron sputtering cathode has been widely used in large area thin film preparation equipment and related industrial fields, such as solar cells, semiconductor devices, display manufacturing and so on.