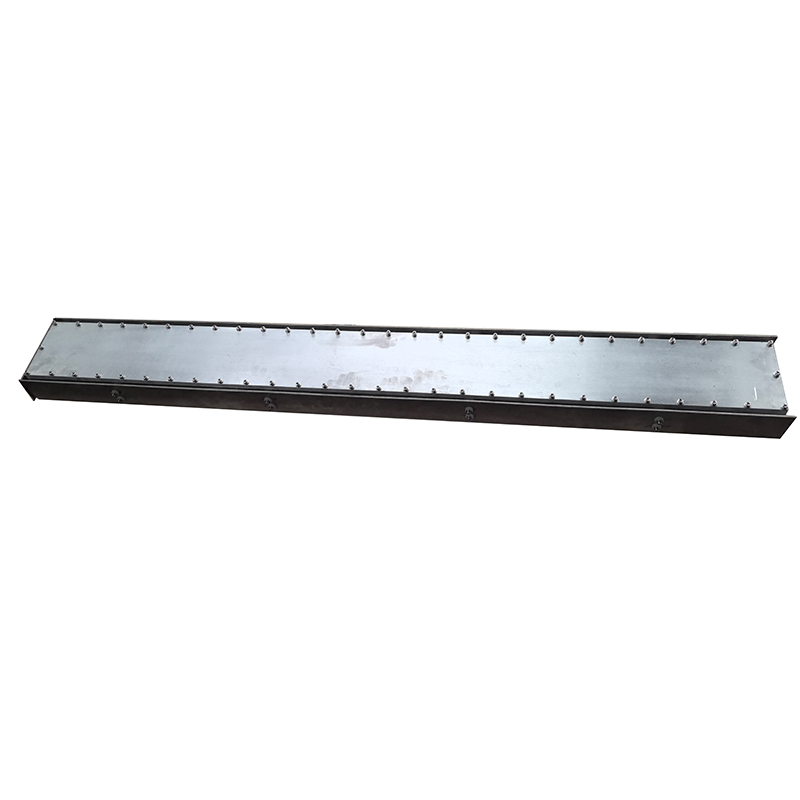

Planar Magnetron Sputtering Cathode: For Superior Thin Film Deposition

A Planar Magnetron Sputtering Cathode is the core component of a magnetron sputtering system, enabling the high-quality, efficient deposition of thin films onto various substrates. It is renowned for its high deposition rates, excellent film uniformity, and extended target material utilization.

Our advanced planar cathodes are engineered for both robust industrial production and precision R&D applications, offering unparalleled reliability and performance in creating functional and decorative coatings.

How Does a Planar Magnetron Sputtering Cathode Work?

The principle of planar magnetron sputtering involves creating a "closed-loop" magnetic field directly above a flat target material (the cathode). When a high voltage is applied in a low-pressure argon gas environment, this magnetic field traps electrons near the target surface.

This confinement dramatically increases the probability of ionizing argon gas atoms, creating a high-density plasma. The ionized argon atoms (Ar+) are then accelerated towards the negatively charged target, bombarding it and ejecting (sputtering) target atoms. These ejected atoms travel and condense on a substrate, forming a thin, uniform, and dense coating.

Advantages of Our Planar Cathode Design

-

High Deposition Rates: The confined plasma leads to a high ion density, resulting in significantly faster sputtering and coating times compared to conventional methods.

-

Excellent Film Uniformity: Our optimized magnetic field design ensures a consistent erosion pattern across the entire target surface, leading to highly uniform thin films over large areas.

-

High Target Material Utilization: The racetrack erosion pattern maximizes the use of the precious target material, reducing waste and operational costs.

-

Low Operating Pressure: Efficient plasma confinement allows for stable operation at lower pressures, resulting in films with fewer impurities and better step coverage.

-

Reduced Substrate Heating: The magnetic field traps electrons, minimizing direct electron bombardment of the substrate, which is crucial for temperature-sensitive materials.

-

Versatility: Compatible with a wide range of conductive target materials (metals like Au, Ag, Cu, Cr, Ti) and, with an RF power source, insulating materials (e.g., Al₂O₃, SiO₂).

Technical Specifications & Customization

Our standard planar magnetron cathodes are available in various sizes and configurations to fit your specific coater and application needs.

Parameter Specification Range

Target Sizes 2-inch diameter for R&D to 500+ mm rectangular for large-area coating

Cooling Efficient closed-loop water cooling for high-power operation

Magnetic Field Balanced or unbalanced magnetic configuration options

Power Compatibility DC, Pulsed DC, and RF (with matching network)

Base Material High-grade stainless steel or copper for optimal cooling

Connections Standard ISO-K, CF flanges, or custom integration

We specialize in custom solutions. We can engineer cathodes for unique geometries, ultra-high vacuum (UHV) compatibility, or specific magnetic field configurations to optimize your coating process.

Primary Applications of Planar Magnetron Sputtering

Our cathodes are used across a vast spectrum of industries and research fields:

-

Semiconductors & Microelectronics: Deposition of conductive layers (Al, Cu), barrier layers (TiN, TaN), and electrodes.

-

Optical Coatings: Creating anti-reflection coatings, mirrors, and filters on glass and lenses.

-

Decorative Coatings: Applying durable and aesthetic coatings like titanium nitride (TiN) for gold-colored finishes on watches, fixtures, and consumer electronics.

-

Tribological Coatings: Hard coatings (e.g., CrN, DLC) for cutting tools, molds, and engine components to reduce wear and friction.

-

Flexible Electronics: Transparent conductive oxides (TCOs) like ITO on PET for touch screens and displays.

-

Research & Development: For developing new materials and novel thin film devices in universities and national labs.

Why Choose Our Planar Magnetron Sputtering Cathodes?

-

Proven Reliability: Built with premium materials and precision engineering for long-term, maintenance-free operation.

-

Optimized Magnetic Field: Our proprietary magnet assembly design ensures a stable plasma and an even erosion profile for maximum performance and target life.

-

Expert Support: Our team of thin film experts provides comprehensive technical support, from installation to process optimization.

-

Global Supply: Hongfeng VAC supports OEMs and research facilities worldwide with a reliable supply of high-quality cathodes and spare parts.

FAQ: Planar Magnetron Sputtering Cathodes

Q1: What is the difference between a planar and a rotary magnetron cathode?

A: A planar cathode uses a flat, static target, while a rotary cathode uses a cylindrical target that rotates. Rotary cathodes offer even higher target utilization and are ideal for very large-area coatings (e.g., architectural glass), but planar cathodes are often more cost-effective and simpler for many standard applications.

Q2: Can I use RF power with your planar magnetron cathodes?

A: Yes. Many of our standard planar cathodes are compatible with RF power supplies for sputtering dielectric materials like oxides and nitrides. We can provide the necessary impedance matching networks.

Q3: How do I determine the right cathode size for my vacuum chamber?

A: The cathode size should be selected based on your substrate size and the required film uniformity. We recommend consulting with our engineering team to select the optimal model for your chamber geometry and process requirements.

Q4: What maintenance is required for a planar magnetron cathode?

A: Primary maintenance involves replacing the target once it is consumed and periodic cleaning of the cathode body and shield to prevent arcing. Our design allows for easy disassembly and servicing.

Ready to enhance your thin film deposition process?

[Request a Quote] or [Contact Our Experts Today] to discuss your application requirements and find the perfect planar magnetron sputtering cathode for your needs.